Systems

The DIANT® LARU – Benchtop LNP Processing

About the DIANT LARU (With NanoFlowSizer™)

The LARU’s continuous nanoparticle processing offers inline dilution, drug loading, and nanoparticle modification, leading to higher efficacy and encapsulation than batch processing.

Nanoparticle Manufacturing with the LARU

The LARU is a pilot-scale system that can continuously produce lipid nanoparticles (LNPs), liposomes, nucleic acid/lipid complexes, polymeric micelles, suspensions, and emulsions.

The LARU:

- Scales up from R&D to commercial cGMP manufacturing

- Performs continuous or batch operations

- Produces nanoparticles of various sizes: ~25 d.nm to >500 d.nm

- Collects volumes as low as 20 mL (short runs)

- Has standard connections for bottles, tubes, or 2D bags for ease of use

Solvent Injection

The LARU features DIANT® Jet technology, a patented single-jet, low flow rate, low dead volume (LDV) solvent injection system for high throughput.

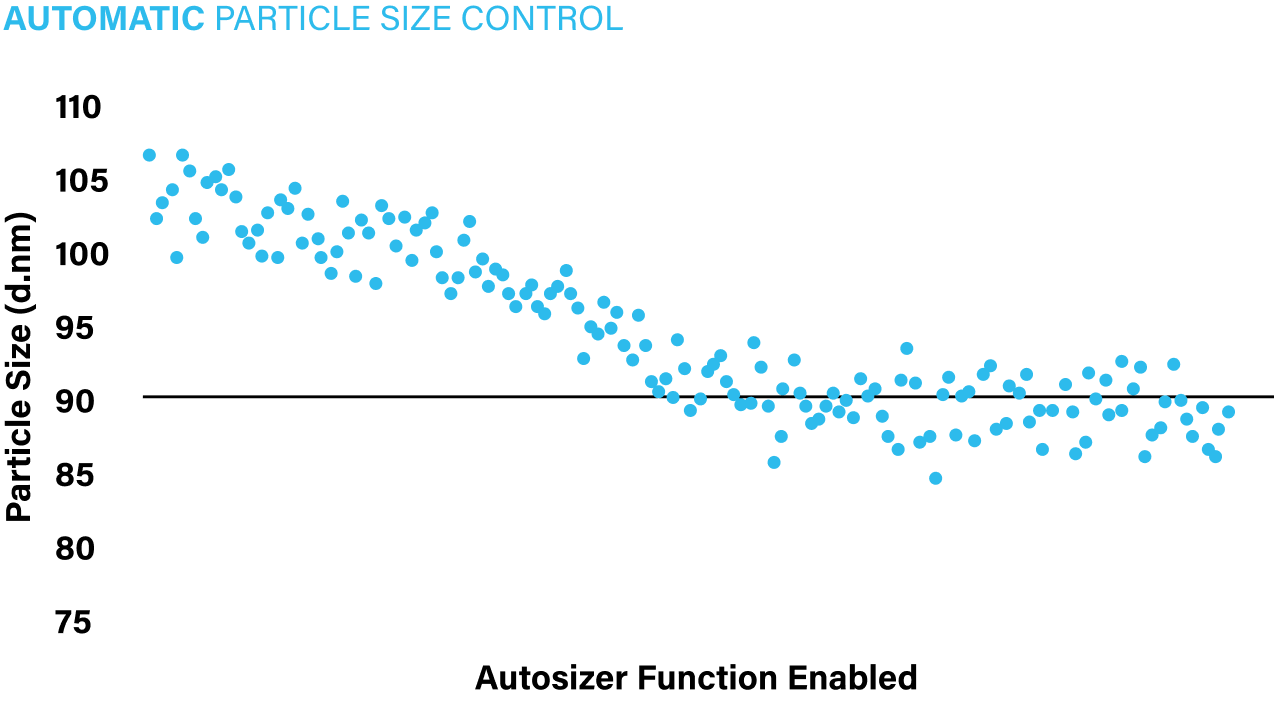

Process Analytical Technology (PAT) via NanoFlowSizer™

As the exclusive distributor of the NanoFlowSizer™ in the United States, DIANT’s systems work with InProcess-LSP’s unique particle size analyzer technology in order to non-invasively characterize nanoparticles inline:

- Integrated, inline particle size control and monitoring with InProcess-LSP’s NanoFlowSizer™, SR-DLS

- Automatic particle size control can enable rapid runs of 20 seconds for determining optimal particle size for your experiments

- Real-time particle monitoring, such as inline lipid analysis

Multiple Program Options

Store and create runtime recipes for producing particles under different flow conditions and set durations.

DIANT® LARU Specifications

Details about the DIANT® LARU, our scalable benchtop nanoparticle synthesis system:

- Dimensions: 30 x 30 x 12 in. (76 x 76 x 30 cm)

- Maximum output flow rate: 400 mL/min

- Solvent flow rate: 20 mL/min

- Flow rate ratio: 2-8

- Dilution port

- Touch-screen HMI

- Data logging

- Voltage & frequency: 100-240 V & 50/60 Hz

DIANT® LARU Add-Ons and Continuous Processing Systems

Optional add-ons that are available for the DIANT® LARU include:

- Customized PAT integration

- Particle size analyzer

- pH monitor/probes

- Conductivity

- Temperature control – Control the temperature of your sample at each stage with the water circulator, sold separately

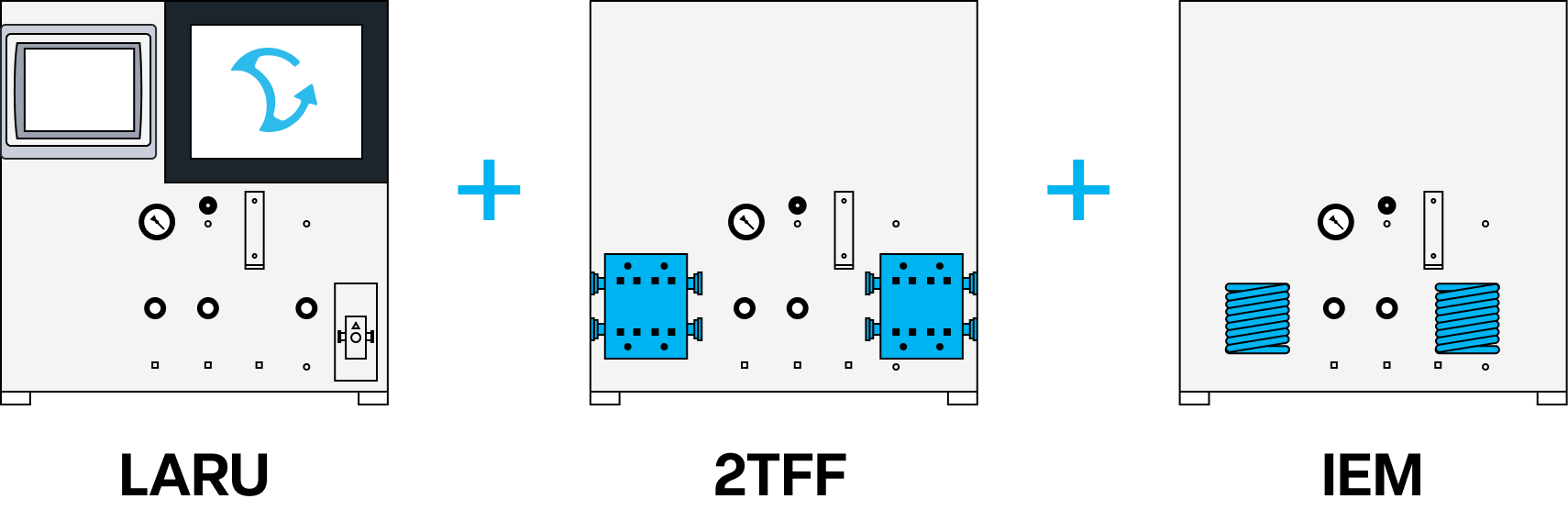

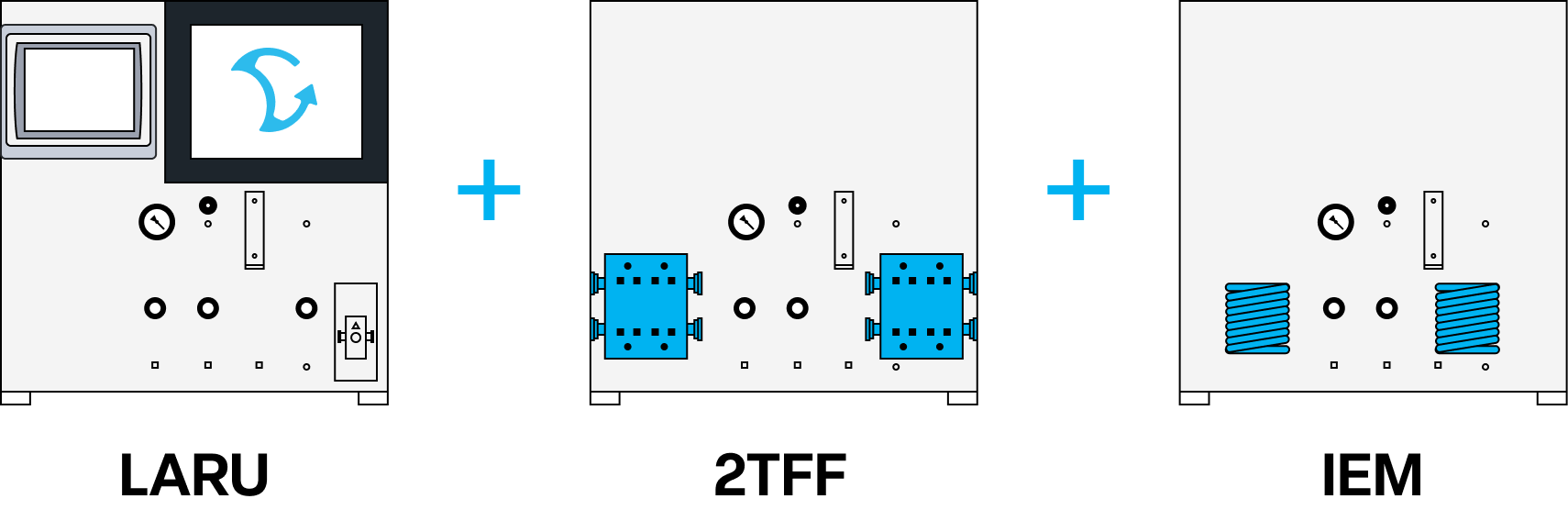

Continuous Processing from LARU to 2TFF and IEM

Single-Pass, Closed Process

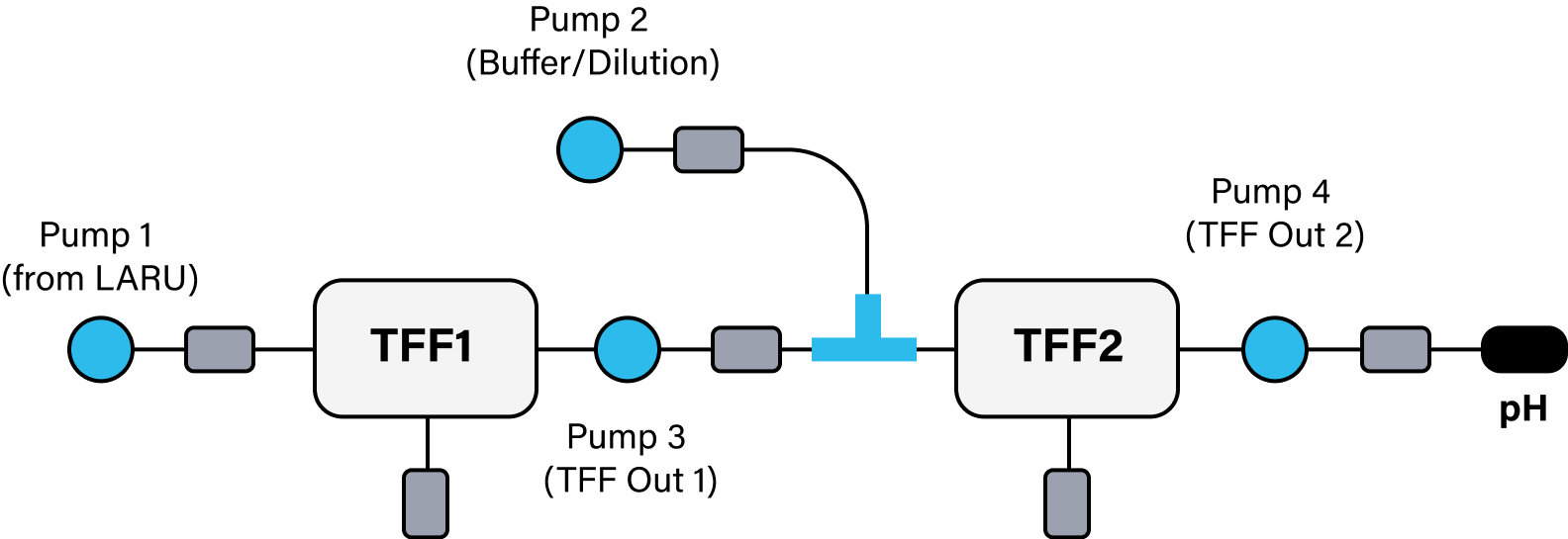

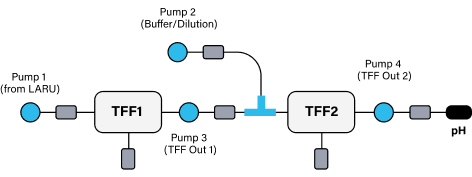

DIANT® LARU + 2TFF

The 2TFF uses a proprietary multi-stage tangential flow filtration system to reduce biofouling and allow for long duration runs. Concentrates particles using a closed system, operating in single-pass mode.

DIANT® LARU + IEM

The DIANT® IEM is a continuous processing system for the

controlled modification of pre-formed vesicular nanoparticles:

- Intravesicular aqueous modifications – small molecules like liposomes can be actively loaded to promote drug encapsulation

- Extravesicular surface modifications – capabilities include adding polymeric coating and active drug moieties

The IEM system can:

- Perform one or several simultaneous nanoparticle modifications as a continuous process

- PEGylate particles, including LNPs, polymeric micelles, and others

- Decorate particles

- Manage growth kinetics

- Salt loading for liposomes

- Surface deposition for LNPs

- Perform PAT – inline UV-Vis with model prediction (optional & customizable)

- Sense pressure, conductivity, and temperature

- Perform inline heat exchange and mixing

- Perform inline bioburden reduction filtration at collection

- Perform inline single-pass concentration