FAQ

Frequently Asked Questions

What is continuous manufacturing?

Continuous manufacturing is a method for producing pharmaceutical products from end-to-end on a single, uninterrupted production line. Where batch manufacturing requires transporting, testing, and re-feeding materials from one process to the next, continuous processes execute all testing, feeding, and processing inline.

How can continuous manufacturing help my current lab and production needs?

Continuous manufacturing can reduce the equipment footprint, time and costs associated with both research and production runs of biologics and pharmaceutical materials.

What is the DIANT Technology difference?

- 1.

Transitioning to continuous manufacturing in the pharmaceutical industry has traditionally been plagued by concerns over regulatory acceptance and potential impacts on timelines. However, there has been a recent push from both industry and regulators to adopt advanced manufacturing technologies, including continuous processing.

- 2.

DIANT Pharma has developed a unique platform for the continuous manufacture of pharmaceutical-grade nanoparticles, including mRNA-LNPs. The system overcomes the challenges of traditional batch processes and offers many additional benefits – such as higher speed and throughput, inline feedback, and simplified scale-up. Specifically, real-time monitoring of continuous manufacturing provides more efficient control over process parameters, avoiding complications associated with scale-up. Moreover, continuous processes can generate more product by simply running for longer periods of time or increasing the volumetric flow rate.

- 3.

DIANT Pharma’s continuous nanoparticle generation system eliminates numerous batch-based unit operations and produces high-quality nanoparticles with improved properties. The technology can be used to produce a variety of nanoparticles, including LNPs, polymeric nanoparticles, and nanosuspensions. At DIANT, we are committed to working closely with our customers to demonstrate the technology, as well as provide support for feasibility studies, product development, and process scale-up.

What are the main benefits of DIANT’s Continuous Processing?

The benefits of DIANT Pharma’s continuous manufacturing solution include

- 1.

Speed and throughput: Continuous manufacturing allows for faster production compared to traditional batch processes, resulting in increased throughput and efficiency. - 2.

Inline feedback: The system provides real-time collection of analytical data, allowing for immediate analysis and monitoring of critical process parameters. This enables better control and adjustment of the manufacturing process. - 3.

Simplified scale-up: Instead of increasing volumes within a reactor, a continuous process can provide more product simply by running for longer, or by increasing the volumetric flow rate. This leads to consistent product quality throughout longer runs. - 4.

Greater control: The smaller reaction volumes and shorter interaction times in continuous processes minimize undesired side-reactions and complications. - 5.

Regulatory acceptance and cost reduction: The Food and Drug Administration (FDA) has been pushing for the adoption of advanced manufacturing technologies – including continuous processing – to improve quality, increase consistency, and reduce cost in the pharmaceutical industry. DIANT Pharma’s continuous manufacturing solution aligns with these goals and can help meet regulatory requirements. - 6.

Reduction in unit operations and human intervention: DIANT Pharma’s continuous manufacturing solution eliminates numerous batch-based unit operations, reducing the number of steps required for nanoparticle generation. This leads to a smaller production footprint, reduced facility and storage requirements, and fewer touchpoints of human interaction, lowering the risks of human error and contamination. - 7.

High-quality outputs: The quality of nanoparticles generated on DIANT Pharma’s continuous system is higher than those obtained from batch processes. In addition, process data provided by inline sensors allow for rapid and precise tuning of nanoparticle properties in real-time.

What Types of Nanoparticles can DIANT’s System generate?

DIANT’s system can generate the following types of nanoparticles:

- 1.

Lipid-based nanoparticles (LNPs): These include lipid nanoparticles encapsulating oligonucleotides for therapeutic and vaccine applications – such as messenger RNA (mRNA). - 2.

Polymeric nanoparticles: DIANT’s system can produce polymeric nanoparticles, which are nanoparticles made from various biocompatible polymers. - 3.

Polymeric micelles: The system can also generate polymeric micelles, which are self-assembled structures formed by amphiphilic block copolymers. - 4.

Polymer/lipid particles: These are nanoparticles that are a combination of polymers and lipids. - 5.

Nanosuspensions: The system is capable of generating nanosuspensions, which are stable colloidal dispersions of nanoparticles in a liquid medium.

What are the advantages of turbulent jet mixers over microfluidic mixers in nanoparticle processing?

DIANT’s continuous manufacturing systems utilize turbulent jet mixers to generate nanoparticles. The advantages of these mixers for nanoparticle formation include:

- 1.

Smaller particle size: Turbulent jet mixers can produce nanoparticles with smaller particle sizes compared to other mixing technologies. This is due mainly to the dramatically increased diffusion efficiency and extremely short residence times within turbulent jet mixers. - 2.

Narrow particle size distribution: The rapid and efficient mixing in turbulent flow conditions reduces the likelihood of aggregation and promotes an even distribution of the components, leading to more uniform particle sizes. - 3.

Higher encapsulation efficiency: The fast and efficient mixing within turbulent jet mixers ensures better interaction between the cargo and the lipid components, leading to increased encapsulation and higher payload capacity. - 4.

Scalability: Unlike microfluidic mixers which need to maintain low Reynolds’ number flow conditions, turbulent jet mixers can be easily scaled up in size for large-scale, higher-flow industrial manufacturing. - 5.

Compatibility with various solvents: Turbulent jet mixers are compatible with a wide range of solvents, including organic solvents commonly used in nanoparticle formulation. This allows for flexibility in the choice of solvents and lipid components, enabling the formulation of a wider variety of high-quality nanoparticles. - 6.

Integration with in-process analytics: Turbulent jet mixers can be integrated with in-process analytics, such as temperature and flow rate monitoring, to ensure precise control and optimization of the nanoparticle formation process. This enables real-time monitoring and adjustment of process parameters for nanoparticle formation, leading to improved reproducibility and quality control.

What services beyond equipment does DIANT offer?

DIANT offers nanoparticle and LNP feasibility studies, particle characterization and custom service contracts to assist our partners in the development of new LNP therapies.

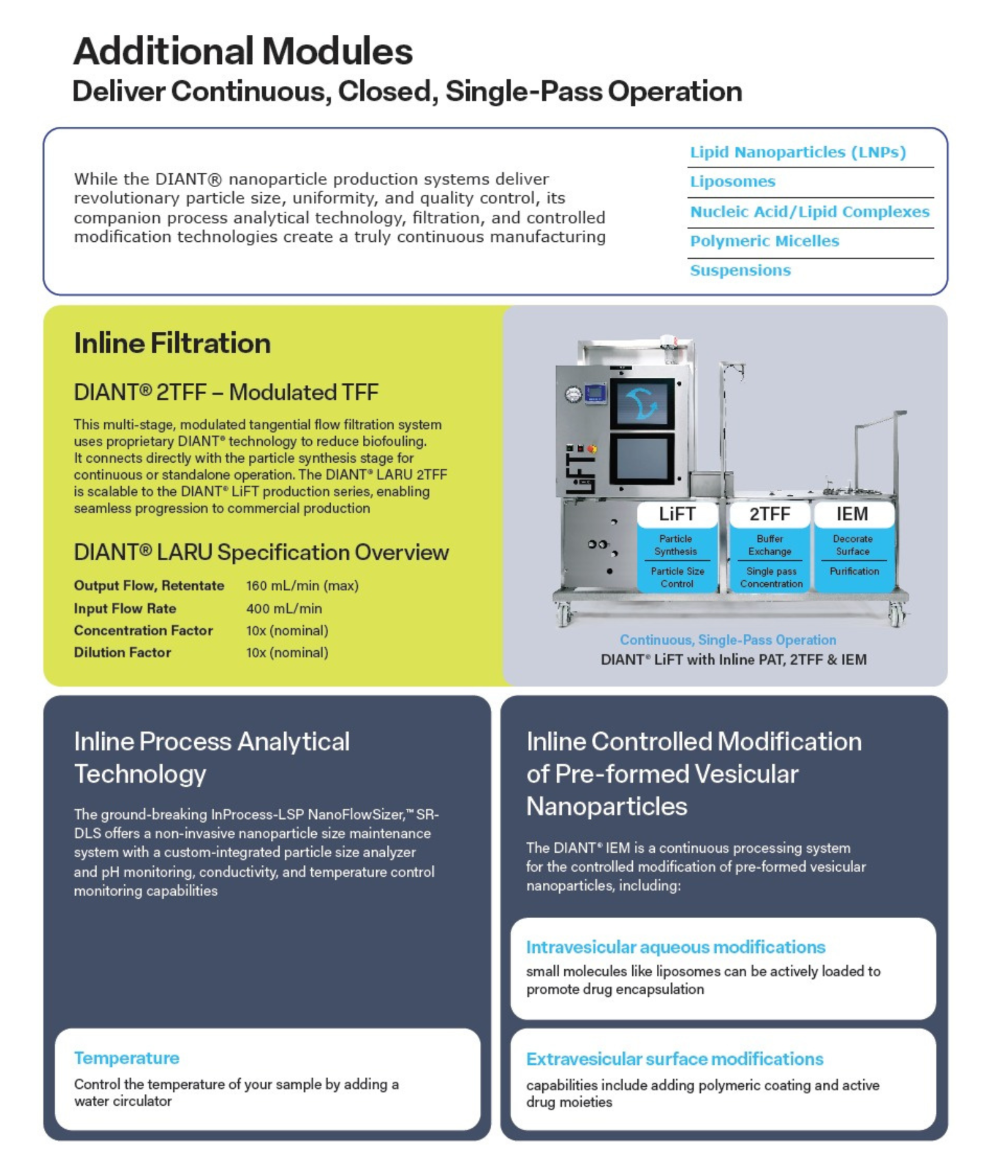

What are the add-on modules?

Regarding DIANT’s equipment, what are the built-in compliance features that facilitate adherence to industry regulations and standards?

The DIANT systems software is CFR Part 11 compliant. Moreover, DIANT has a variety of quality assurance procedures and documentation, starting with the design qualification to the factory acceptance test, site acceptance testing, IQ/OQ documentation and PQ support. The groundbreaking process analytical technology feature creates a continuous control on the product quality and desired specifications. None other particle processing equipment has such capabilities. DIANT takes the guessing game out of processing and enables regulatory quality compliance at a continuous level.

Do you think continuous LNP production will have a higher impact within biopharma or rather in other industries?

Continuous nanoparticle production processes will benefit many different industries. Our focus is within the biopharma and cell & gene therapy applications; however we have clients throughout who are impressed and interested by the DIANT processing systems and our expertise.

What are the critical quality attributes of nanoparticles and nanoparticle processing?

- 1.

Size: The size of nanoparticles is a critical attribute as it affects their stability, biodistribution, and cellular uptake. Nanoparticles with smaller sizes generally have better cellular uptake and can penetrate tissues more effectively. - 2.

Shape: The shape of nanoparticles can influence their interactions with cells and tissues. Different shapes, such as spheres, rods, or discs, can have different cellular uptake mechanisms and biodistribution profiles. - 3.

Surface charge: The surface charge of nanoparticles, often determined by the presence of functional groups or coatings, can affect their stability, cellular uptake, and interaction with biological barriers. Positively charged nanoparticles may have enhanced cellular uptake, while negatively charged nanoparticles may have improved stability. - 4.

Surface chemistry: The surface chemistry of nanoparticles plays a crucial role in their interactions with biological systems. Functional groups or coatings on the nanoparticle surface can enable specific targeting, enhance stability, or control drug release. - 5.

Drug loading capacity: For drug delivery nanoparticles, the ability to efficiently load and release therapeutic agents is a critical attribute. High drug loading capacity ensures effective delivery of therapeutic payloads to the target site. - 6.

Drug release kinetics: The release kinetics of drugs from nanoparticles can impact their therapeutic efficacy. Controlled release of drugs over a desired period can optimize drug concentration at the target site and minimize off-target effects. - 7.

Stability: The stability of nanoparticles is important to ensure their integrity during storage and transportation. Stability can be influenced by factors such as aggregation, degradation, or changes in physicochemical properties over time. - 8.

Biocompatibility: Nanoparticles should be biocompatible to minimize adverse effects and ensure their safe use in vivo. Biocompatibility includes considerations such as low toxicity, minimal immune response, and absence of long-term adverse effects. - 9.

Targeting ability: Targeting ability refers to the ability of nanoparticles to specifically accumulate at the desired site of action, such as a tumor or inflamed tissue. Targeting ligands or functional groups on the nanoparticle surface can facilitate specific interactions with target cells or tissues. - 10.

Manufacturing reproducibility: Consistency in manufacturing processes and reproducibility of nanoparticle properties are critical quality attributes. This ensures batch-to-batch consistency and reliable performance of nanoparticles for therapeutic applications. - 11.

Stimulus response material or structure: Nanoparticles should be able to respond to specific stimuli, such as enzymes, pH, temperature, optics, and magnetism. This allows for targeted drug delivery and controlled release at the desired site. - 12.

Adjustable surface charge: The surface charge of nanoparticles can be adjusted to enhance their stability, interaction with biological systems, and cellular uptake. - 13.

High encapsulation capacity: Nanoparticles should have a high capacity to encapsulate drugs or therapeutic agents, ensuring efficient delivery and maximum therapeutic effect. - 14.

Degradability: Nanoparticles should be biodegradable, allowing for their safe elimination from the body after drug release. - 15.

Low toxicity: Nanoparticles should have low toxicity to minimize adverse effects on the body. - 16.

Controlled drug release: Nanoparticles should have the ability to release drugs in a controlled manner, either in response to specific stimuli or over a prolonged period of time.

It is important to note that the specific critical quality attributes may vary depending on the type of nanoparticles and their intended application